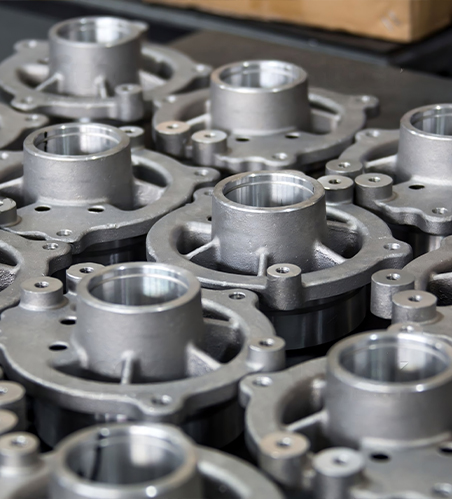

Reliability of products is most important in the cutthroat manufacturing environment today. Cast components are an important part of many sectors of industry, including automotive, aerospace, medical device, and construction; a single small flaw can result in significant safety or performance concerns.

Casting is a very cost-effective way of manufacturing complex shapes. Provided it is handled correctly, it will create defects such as porosity, shrinkage, or cracks.

This is where you, the casting quality control, come into play using a systematic method at the inspection stage for raw materials, right through to post-processing inspection. You can reduce the defects, reduce your costs, and provide a longer-term service capability.

In this blog, we will discuss why casting quality control is important, the most common casting defects, how to mitigate them, and the sequential steps to have reliable and good quality production.

Why is Casting Quality Control Crucial?

Utilizing a structured performance control plan in casting can bring both short-term and long-term advantages and benefits:

- Better Reliability of the product: Components are resistant to mechanical stresses (as well as corrosion and fatigue) with time.

- Less Work: Early detection of defects implies reduced rework, reduced scrap, and reduced warranty claims.

- Trust of the Company: Guarantee of continued quality guarantees long-term trust among your customers and continued business relations.

- Global Competitiveness: To the Indian casting foundries, adherence to international standards like ISO, ASTM, and DIN can only translate to success in the export market.

In short, no matter how good the design and materials are, they cannot stand the test of time unless the performance of the casting is taken care of.

Common Casting Defects and Their Prevention

Defects are an inherent risk of casting, but their consequences can be mitigated using preventive measures. Below, we identify the most frequent problems and the means of prevention:

| Defect | Description (Short) | Causes (Key) | Prevention (Quick) |

| Porosity | Small voids in metal | Poor venting, moisture, and gas impurities | Dry molds, proper venting, control temp |

| Shrinkage | Cavities from uneven cooling | Lack of molten feed, cooling issues | Use risers, optimize cooling |

| Cracks (Hot Tears) | Stress cracks during cooling | Uneven cooling, poor mold design | Allow contraction, control solidification |

| Cold Shuts | Seam where metal didn’t fuse | Low temp, poor flow in mold | Raise temp, improve flow design |

| Inclusions | Non-metallic particles inside | Impure metal, slag entry | Use clean alloys, filters, and careful pouring |

| Dimensional Issues | Wrong size/tolerance | Die wear, poor mold design | CAD + simulation, maintain molds |

| Surface Defects | Poor finish, uneven surface | Faulty patterns, bad cleaning | Visual checks, proper mold handling |

1. Porosity: Small holes in the metal that are formed by confined gases.

- Causes: improper venting, dampness of the mold material, and pouring at the wrong temperature.

- Preventions: Use dried molds, optimal mold design with venting, and control pouring temperature.

2. Shrinkage: Voids that are created as a result of differential cooling.

- Causes: Insufficient molten feed into the void or shrinkage cavity during the solidification.

- Prevention: Install risers to feed molten metal to the void and to regulate the cooling rates.

3. Cracks (Hot Tears): Cracks caused by residual stress during cooling.

- Causes: Non-uniform cooling or mold design that restricts contraction of the mold.

- Prevention: Modify the design of the mold to allow for thermal contraction and control cooling rates.

4. Cold Shuts: Apparent lines where streams of molten metal did not fuse.

- Causes: Low pouring temperature or changes in the complexity of the molding design.

- Prevention: Rising pouring temperature, increasing flow lines, and pulling speed.

5. Inclusions: Non-metallic particles embedded in the casting.

- Causes: Impurities within the raw materials, slag during pouring.

- Prevention: Use good-quality alloys, filtration, and pouring methods.

6. Dimensional Problems: Deviations in shape or tolerance.

- Causes: Poor design of mold, die wear, or unaccounted shrinkage.

- Prevention: Regular maintenance of molds and CAD with casting simulation.

7. Surface Defects: Cosmetic defects, such as bad finishes, sand holes.

- Causes: Bad molding patterns, bad cleaning procedures.

- Prevention: The eye check and keeping molds.

Manufacturers can significantly decrease the number of defects and be able to guarantee reliability in the process should they proactively take preventive steps.

The Multi-Stage Casting Quality Control Process

Casting quality assurance is not a single event but a multi-staged process that begins before the melt is poured and encompasses the entire lifecycle of the part.

1. Pre-Casting Stage: Planning the foundation

- Raw Material Assessment: Ensuring the chemical analysis, purity of the alloys assists in preserving the consistency, preempting the occurrence of metallurgical issues.

- Design Evaluation and Virtual Simulation: Designing with the help of computer-aided engineering software (CAE) enables the design team to anticipate and solve problems such as shrinkage and entrapment of gases, even before the production process begins.

- Mould Design and Management: Good mould design will facilitate a good circulation of metal and also enable prescribed ventilation. In addition, routine and consistent maintenance can help lessen costly dimensional errors.

2. In-Process Stage: Monitoring Production

- Process Monitoring: The parameters, including temperature, pouring rate, and pressure, are monitored in real-time and allow immediate identification of anomalies.

- Statistical Process Control (SPC): Manufacturing organizations can use statistical tools to identify deviations sooner, so corrections can be made in a timely manner.

3. The Post-Casting Stage: Completing your Trustworthiness

- Visual & Dimensional Inspection: detect surface defects, dimension inspection of surface by Coordinate Measuring Machines (CMM), 3-D scanning.

- Non-Destructive Testing (NDT):

- Internal porosity, inclusions, can be found via radiography (X-ray).

- Ultrasonics is used to find voids and measure thickness.

- Magnetic Particle Inspection is applied to locate defects in ferrous metals.

- Heat Treatment: changes properties from the casting stage, including strength, toughness, and hardness.

- Leak testing: A requirement for castings needing to be airtight or watertight is often done on castings.

As you can see, these stages create a foundation of reliability to ensure quality at every production level.

Future of Casting Quality Control in India

The future of Indian foundries depends on better technologies in the quality assurance area. Some trends are:

- AI-Based Defect Prediction: Machine learning models can predict defects prior to beginning production.

- 3D Printing of Molds: This gives dimensional accuracy while reducing cycle times.

- Robotic Inspection: This automates non-destructive testing (NDT) and thus makes it more precise.

- Environmentally friendly: Environmentally friendly binders, energy conservation furnaces, scrap metal recycling.

The Make in India, Aatmanirbhar Bharat objectives will make India a manufacturing destination, but introducing casting quality control systems will significantly contribute to India’s growth plans.

Conclusion

The casting process is essential in most industries, and much relies on casting quality control to produce successful casting products.

Having combined testing of raw materials, controlling the casting processes, inspection, and introduction of digital technologies into the process, the manufacturers can make significant advances in terms of product reliability.

In the case of India which is emerging as the world’s powerhouse in terms of casting, a good quality system is a strategic asset. Better reliability will mean safer cars, better infrastructure, and increased confidence in the products made in India among other nations.

FAQs

1. What is casting quality control?

Casting quality control refers to the process of inspecting, monitoring, and improving each stage of casting — from raw material selection to final inspection — to ensure defect-free, reliable, and durable cast products.

2. Why is quality control important in casting?

Quality control ensures that cast components meet required standards, reducing defects like porosity or cracks. It improves product reliability, lowers rework and scrap costs, and helps manufacturers maintain customer trust and global competitiveness.

3. How is quality control in casting?

Common casting defects include porosity, shrinkage, cracks, cold shuts, inclusions, dimensional errors, and surface defects. Each of these can affect the strength, appearance, or performance of the casting.

4. What testing methods are used in casting quality control?

Non-destructive testing (NDT) methods like radiography, ultrasonic testing, and magnetic particle inspection are widely used to detect internal and surface defects without damaging the casting.

5. What is the role of simulation in casting quality control?

Simulation tools help engineers visualize and correct potential issues such as shrinkage or gas entrapment before production, reducing trial-and-error and improving first-time quality success.

6. How is heat treatment important after casting?

Heat treatment improves mechanical properties like strength, hardness, and toughness. It helps relieve internal stresses and ensures the casting performs reliably in demanding conditions.